PI Name & Affiliation:

Dr. A. John Rajan,

Professor

School of Mechanical Engineering (SMEC)

Vellore Institute of Technology, India

Co-PI Name & Affiliations:

Dr. T. Sampath Kumar,

Associate Professor

Dr. A. Vinoth Jebaraj,

Associate Professor

School of Mechanical Engineering (SMEC)

Vellore Institute of Technology, India

Funding Agency: ISRO

Scheme: Respond

Overlay: Rs. 16,32,000

Duration of the Project: 2 Years

Dr. A. John Rajan

Dr. T. Sampath Kumar

Dr. A. Vinoth Jebaraj

Project Description

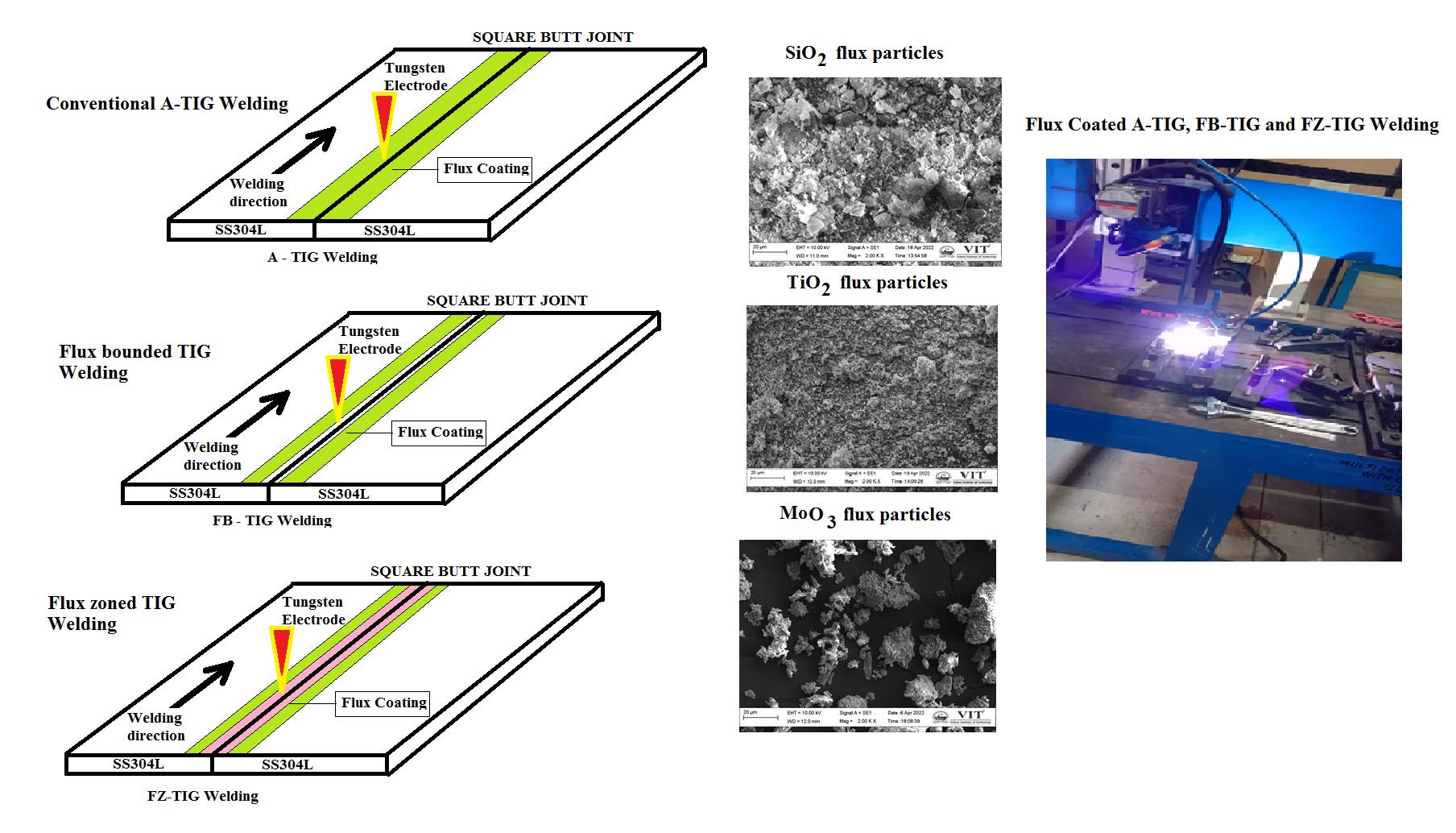

This project mainly focuses the optimization of process parameters involved in the activated gas tungsten arc welding, flux bounded and flux zoned gas tungsten arc welding of austenitic stainless steel AISI 304L material. Manual welding will be performed on the rolled plates of thicknesses 3mm, 4mm, 5mm and 8mm using the flux coatings SiO2, TiO2, MoO3 and mixed flux components to fabricate the weld joints. The main outcome of this work is to achieve the higher depth of penetration with minimum width on the weld through the use of optimized welding heat input, proper selection of solvent flux combinations, and through the use of mixed shielding gas with appropriate ratio. The soundness of the weldment will be analyzed based on the resultant microstructure with special reference to the changes in fusion zone and heat affected zone. Further, the mechanical properties of the weldment will be investigated through the use of Vicker’s micro hardness test; room temperature tensile test and the formability test i.e. three point bending on the weld specimens. This study will deliver the welding procedure specification for the 3mm, 4mm 5mm and 8mm thick stainless steel AISI 304L plates. The optimum findings from this investigation will be implemented in the fabrication of AISI 304L weld joints used in the aerospace applications.