PI Name & Affiliation:

Dr. Chinmaya Prasad Mohanty,

Assistant Professor (Senior)

School of Mechanical Engineering (SMEC)

Vellore Institute of Technology, India

Co-PI Name & Affiliation:

Dr. A. Raja Annamalai,

Associate Professor (Senior)

School of Mechanical Engineering (SMEC)

Vellore Institute of Technology, India

Funding Agency: Aeronautics Research and Development Board, DRDO

Overlay: Rs. 10,52,280

Duration of the Project: 3 Years

Dr. Chinmaya Prasad Mohanty

Dr. A. Raja Annamalai

Project Description

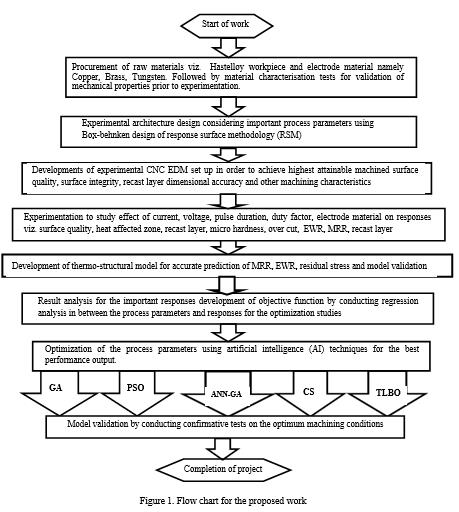

To meet stringent aerospace applications, the requisite of sustainable machining, and machinability exploration, an experimental investigation on Hastelloy alloy is proposed. Outcomes of essential process parameters viz. voltage (U), discharge current (I), pulse-on-time (Ton), duty factor (τ), and electrode material shall be studied on the responses viz., surface roughness (SR), surface crack density (SCD), recast layer (RL), heat affected zone (HAZ), the microhardness of the machined surface (MH), material removal rate (MRR), electrode wear ratio (EWR), overcut, etc. A scanning electron microscope (SEM) Investigation shall be carried out to analyze the pre-machining and post-machining scenarios on the machined surface. A thermo-structural numerical model shall be developed to predict the EDM process's essential performance measures such as MRR, EWR, residual stress (RS), surface roughness developed during machining and shall be validated by comparing with experimental results. Finally, the study results shall be predicted using artificial intelligence (AI) like ANN, GA, PSO, etc.