PI Name & Affiliation:

Dr. Bibhuti Bhusan Sahoo

Associate Professor,

School of Mechanical Engineering (SMEC)

Co-PI Name & Affiliation:

Dr. Dharmendra Kumar Bal

School of Chemical Engineering (SCHEME)

Funding Agency: DST-SERB

Scheme: Core Research Grant (CRG)

Overlay: Rs. 30,08,108

Duration of the Project: 3 Years

Dr. Bibhuti B. Sahoo

Dr. Dharmendra K. Bal

Project Description

Biogas, a promising renewable energy source for thermal and electricity generation applications, has significant potential to be in the global energy mix. Biogas is a mixture of gases contains concentrations of 40-75% methane (CH4), 15-60% carbon dioxide (CO2), 0.5-1.0% hydrogen sulphide (H2S) and traces of moisture and other gases. Due to the presence of non-combustible CO2 in the low heating content, biogas restrains its compressibility and hence, this makes biogas storing very difficult in containers. Again, when the H2S contained biogas fueled to produce heat and power, the engines get corrosion and degrade the lubricating oil. Also, the combustion of H2S leads to the formation of sulphur dioxide (SO2). Therefore, it is necessary to upgrade raw biogas to a high-grade biogas fuel by removing the CO2 and H2S content from it. Now, it can be easily compressed, stored in containers and transported to be used as fuel vehicle, cooking or electricity generation applications

Recently, some biogas upgrading technologies are in operation such as physical, chemical, and biological, etc. However, their efficiency and operational conditions, investment and maintenance costs are very high. Therefore, the biogas upgrading market and technologies demand a cost-effective method. To overcome the drawbacks of available biogas updating technologies the development of a new, low-cost and simple biogas upgrading process is on demand by the World.

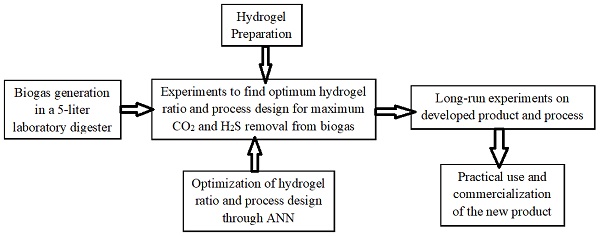

The proposed work tries to solve this problem by preparing a hydrogel of polyacrylamide polymer and the crosslinking solution to capture the CO2 and H2S composition of biogas. It is a low-cost and low-energy consuming process that will be carried out with the following:

- i. Experimental work to develop the optimum hydrogel ratio and process design to remove maximum CO2 and H2S from biogas by considering all technical parameters.

- ii. Stability/ long-run test of the designed technology for the commercialization of the new proposed product.

The success of the project shall be beneficial to the society, compressed biogas production units, automobile and stationary engine manufacturers to adopt a low-cost renewable fuel for all types of requirements such as heat and power, and transportation. The extensive use of renewable biogas will reduce the net CO2 and poisonous SO2 addition into the atmosphere.