PI Name & Affiliation:

Dr. M. Arivarasu,

Associate Professor,

Center for Innovative Manufacturing Research (CIMR), School of Mechanical Engineering

(SMEC)

Co-PI Name & Affiliation:

Dr. N. Arivazhagan

Higher Academic Grade

School of Mechanical Engineering (SMEC)

Dr. M. Nageswara Rao,

Senior Professor

School of Mechanical Engineering (SMEC)

Polish Investigator Name & Affiliation:

Prof. Andrzej Nowotnik,

Professor,

Rzeszow University of Technology, Poland

Funding Agency: DST-NAWA

Scheme: International Bilateral Co-operation

Overlay: Rs. 16,50,000

Duration of the Project: 2 Years

Dr. Arivarasu M

Dr. Andrzej Nowotnik

Project Description

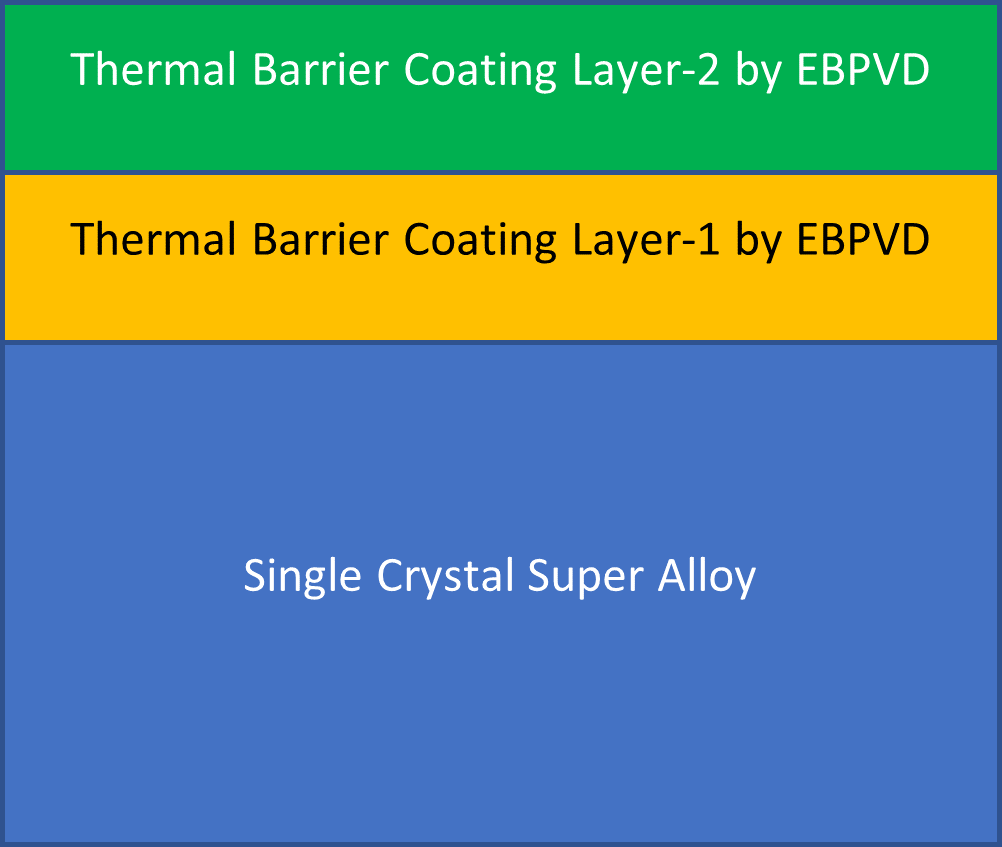

Efficiency and performance of advanced gas turbines for aircrafts and land based applications can be considerably increased if higher gas temperatures are applied. Usage of thermal barrier coatings (TBCs) on superalloy turbine blades and vanes makes such an increase of gas temperature possible owing to a remarkable effect of temperature drop of the metal components. The Electron beam Physical Vapour Deposition (EB-PVD) process offers the advantage of a superior strain and thermo shock tolerant behavior of the coatings due to their columnar microstructure. This collaborative research proposes a two source evaporation to create sequential environmental barrier coatings on the 21st century single crystal superalloy and evaluating its hot corrosion and erosion behaviour in aero engine environment.